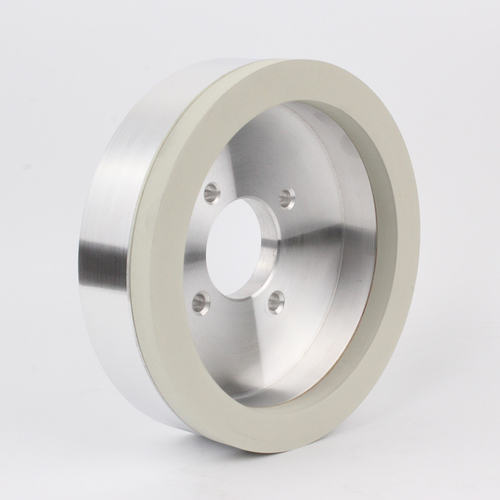

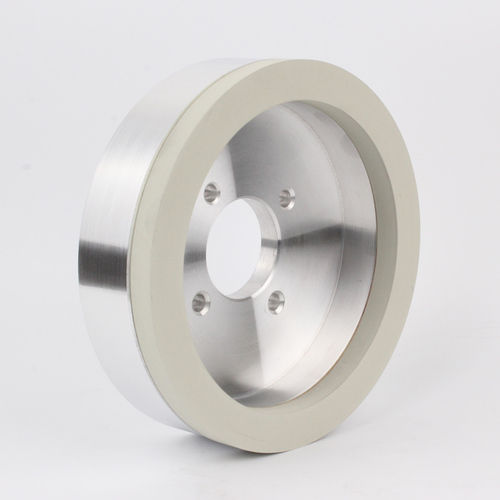

Pcd Grinding Wheel

Pcd Grinding Wheel Specification

- Harness

- High hardness

- Application

- Grinding and cutting

- Depth of Working Layer

- 3-10 mm

- RPM

- 3000-6000

- Viscosity

- Standard

- Width

- Customisable

- Abrasive Grit Size

- Varied grit sizes available

- Hole Size

- Customisable

- Width of Working Layer

- 15-50 mm

- Bond Type

- Resin Bond

- Thickness

- 10-500 Millimeter (mm)

- Product Type

- Diamond Wheel

- Size

- Available in multiple sizes

- Grain Size

- Fine to Coarse

- Shape

- Round

- Bonding Agent

- High strength resin

- Abrasive

- Intermediate Grinding Action

- Abrasive Concentration

- Diamond

- Wheel Size

- Up to 500 mm

- Texture

- Smooth finish

Pcd Grinding Wheel Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 20 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Box.

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About Pcd Grinding Wheel

Pcd Grinding Wheel

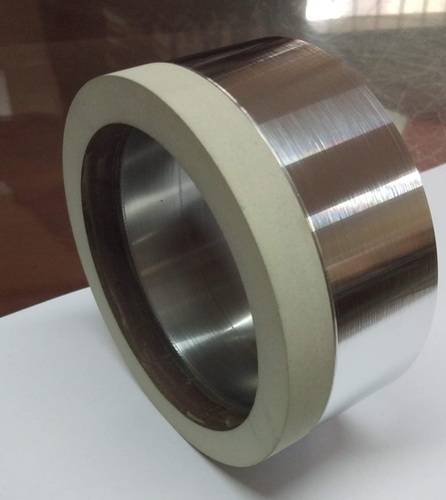

The vitrified diamond wheels are made by low temperature vitrified bond and high quality CBN with the features of excellent sharpness, long durability and easy to be trued and dressed.

Vitrified wheels have a glass bond composition. Vitrified wheels hold form extremely well and produce a high ratio of stock removal to wheel use. Vitrified wheels are commonly used for precision grinding in the tool and die market.

Vitrified diamond grinding wheels are most suited for grinding of very hard Ceramic and Carbide materials. Applications include grinding of PCD and PCBN cutting toolings, structural ceramic components, and Carbides.

Exceptional Grinding Precision

Manufactured using Polycrystalline Diamond (PCD), this grinding wheel achieves exceptionally precise cutting results, minimizing material chipping and ensuring a smooth surface finish. Its intermediate grinding action makes it suitable for a range of industrial needs, from shaping to finishing.

Robust Compatibility and Customisation

PCD Grinding Wheels are designed to work seamlessly with both CNC grinding machines and manual grinders. With customisable width, hole size, thickness, and grit size, companies can select the ideal wheel configuration for their specific machining and grinding requirements.

Extended Tool Life and Low Maintenance

Engineered for extended edge retention, these wheels require less frequent replacement, reducing overall downtime. Their non-corrosive materials and easy cleaning make maintenance simple and cost-effective, keeping operations efficient for longer periods.

FAQs of Pcd Grinding Wheel:

Q: How do I choose the correct PCD Grinding Wheel size and grit for my application?

A: When selecting a PCD Grinding Wheel, consider the material to be worked on and the desired surface finish. Wheels are available in multiple sizes (up to 500 mm), thicknesses (10500 mm), and varied grit sizes from fine to coarse, allowing you to match abrasive strength to your grinding or cutting needs.Q: What benefits does Polycrystalline Diamond (PCD) offer compared to traditional abrasives?

A: PCD provides superior hardness, enhanced edge retention, and exceptional stability at high speeds. This results in extended tool life, less frequent wheel changes, and a smoother finish with minimal chipping, outperforming conventional bonded abrasives in demanding industrial environments.Q: When should I replace a PCD Grinding Wheel?

A: Replace the wheel if you notice excessive wear on the working layer (depth of 310 mm), diminished cutting efficiency, or increased chipping. Regular inspection after heavy usage ensures optimal tool performance and safety.Q: Where can PCD Grinding Wheels be used?

A: These wheels are suitable for use in industrial settings, particularly on CNC grinding machines and manual grinders. They are ideal for grinding, cutting, and finishing across diverse manufacturing sectors demanding precision and durability.Q: What is the recommended cleaning and maintenance process for these wheels?

A: PCD Grinding Wheels require minimal maintenance. After use, clean them using standard industrial methods, such as compressed air or gentle brushing, to remove debris. Their non-corrosive construction makes them easy to maintain and promotes longevity.Q: How does the resin bond and high-strength bonding agent improve wheel performance?

A: The resin bond combined with high-strength bonding agents provides robust wheel integrity, enhancing stability at RPMs of 30006000 and supporting smooth grinding action. This ensures consistent intermediate abrasive action and reliable results even under demanding operational conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vitrified Bond Diamond Grinding Wheel Category

Vitrified Bond Diamond Wheel For Pcd Tools

Minimum Order Quantity : 1 Piece

Thickness : 6.6 Millimeter (mm)

Product Type : Diamond Wheel

Abrasive : Very Tough Abrasive

Shape : Round

Application : Angular Head Grinding

Vitrified Bond Grinding Wheels For PCD Tools

Minimum Order Quantity : 1 Piece

Thickness : 1050 Millimeter (mm)

Product Type : Grinding Wheel

Abrasive : Intermediate Grinding Action

Shape : Round

Vitrified Bond Diamond Grinding Wheel

Minimum Order Quantity : 1 Piece

Thickness : 10540 Millimeter (mm)

Product Type : Squaring Wheel

Abrasive : Intermediate Grinding Action

Shape : Round

Application : Heavy Duty Work

Vitrified Bond Grinding Wheel

Minimum Order Quantity : 1 Piece

Thickness : 6.6 Millimeter (mm)

Product Type : Bond Wheel

Abrasive : Very Tough Abrasive

Shape : Round

Application : Angular Head Grinding

Send Inquiry

Send Inquiry