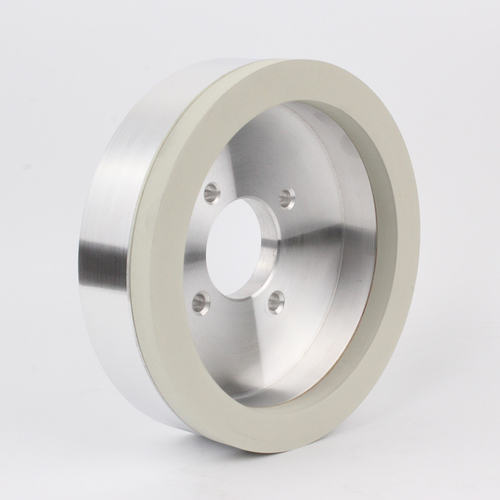

Vitrified Bond Diamond Wheel For Pcd Tools

Vitrified Bond Diamond Wheel For Pcd Tools Specification

- Shape

- Round

- Hole Size

- As per order

- Depth of Working Layer

- Up to 10 mm

- Application

- Angular Head Grinding

- Texture

- Consistent and Uniform

- Harness

- High Hardness

- Bonding Agent

- Vitrified Ceramic

- Abrasive Grit Size

- Available in multiple grits

- Product Type

- Diamond Wheel

- Width of Working Layer

- Customizable

- Size

- Customizable

- Abrasive

- Very Tough Abrasive

- Grain Size

- Fine to Coarse (as per requirement)

- Bond Type

- Vitrified Bond

- Thickness

- 6.6 Millimeter (mm)

- RPM

- Up to 3000 RPM

- Wheel Size

- Custom Dimensions Available

- Abrasive Concentration

- Standard/High upon request

- Max Operating Speed

- 35 m/s

- Tolerance

- High Precision

- Cutting Efficiency

- High

- Color

- Brown/Black (As shown in image)

- Compatible Material

- PCD, PCBN, Carbide, Ceramics

- Surface Finish Quality

- Superior

- Cooling Requirement

- Wet or Dry Grinding

- Longevity

- Extended Service Life

- Heat Resistance

- Excellent

Vitrified Bond Diamond Wheel For Pcd Tools Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 20 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Box.

- Main Domestic Market

- All India

About Vitrified Bond Diamond Wheel For Pcd Tools

Vitrified Bond Diamond Wheel For Pcd Tools

The vitrified bond diamond wheels are made by low temperature vitrified bond and high quality CBN with the features of excellent sharpness, long durability and easy to be trued and dressed.

Vitrified wheels have a glass bond composition. Vitrified wheels hold form extremely well and produce a high ratio of stock removal to wheel use. Vitrified wheels are commonly used for precision grinding in the tool and die market.

Superior Performance for Demanding Applications

This diamond wheel leverages a vitrified bond and very tough abrasive grains, allowing it to handle angular head grinding for PCD, PCBN, carbide, and ceramics with remarkable efficiency. Users benefit from excellent heat resistance, extended longevity, and the ability to maintain high-precision tolerances even at speeds up to 35 m/s. Its customizable specifications make it suitable for a variety of industrial environments.

Consistency and Customization for Every Requirement

Crafted with consistent texture and uniform grain distribution, the wheel offers customizable dimensions, depth, and abrasive grit size. This flexibility enables optimal adaptation for specific grinding needs, whether you require fine finishing or aggressive material removal. The color options of brown or black and the customizable working layer further enhance suitability for different machine types and tasks.

FAQs of Vitrified Bond Diamond Wheel For Pcd Tools:

Q: How does the vitrified bond in the diamond wheel improve tool performance?

A: The vitrified bond provides a strong, stable structure that holds abrasive grains firmly in place, resulting in enhanced heat resistance, improved cutting efficiency, and superior surface finish. This ensures high precision during grinding and contributes to the wheels longer service life.Q: What materials is this diamond wheel best suited to grind?

A: This wheel is specifically designed for grinding PCD, PCBN, carbide, and ceramics. Its tough abrasive grains and vitrified bond make it ideal for processing hard and ultra-hard materials in a variety of precision applications.Q: When should wet versus dry grinding be used with this wheel?

A: Both wet and dry grinding are supported by this wheel. Wet grinding is recommended where heat control and maximum surface finish are critical. Dry grinding is appropriate for certain rapid operations when coolant or lubrication is either unnecessary or unavailable.Q: Where can this product be applied across industries?

A: The wheel is suitable for industries such as tool manufacturing, automotive, aerospace, and precision engineering, where angular head grinding and high-tolerance finishing of advanced materials are required. It is widely distributed across India by manufacturers, suppliers, and exporters.Q: What is the process for ordering customized sizes or grit options?

A: To order custom dimensions, grit sizes, working layer widths, or hole sizes, contact the supplier or manufacturer with your specific requirements. They will advise on available options and production lead times, ensuring the wheel meets your precise operational needs.Q: How does using this diamond wheel benefit grinding operations?

A: Operators benefit from high cutting efficiency, consistent quality, and minimal downtime due to the wheels extended service life and superior heat resistance. It helps achieve a high-quality finish, tight tolerances, and optimal productivity for demanding grinding tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vitrified Bond Diamond Grinding Wheel Category

Vitrified Bond Diamond Grinding Wheel

Minimum Order Quantity : 1 Piece

Product Type : Diamond Wheel

Abrasive : Very Tough Abrasive

Shape : Round

Thickness : 6.6 Millimeter (mm)

Vitrified Bond Wheel

Minimum Order Quantity : 1 Piece

Product Type : Diamond Wheel

Abrasive : Very Tough Abrasive

Shape : Round

Thickness : 6.6 Millimeter (mm)

Vitrified Bond Grinding Wheels For PCD Tools

Minimum Order Quantity : 1 Piece

Product Type : Grinding Wheel

Abrasive : Intermediate Grinding Action

Shape : Round

Thickness : 1050 Millimeter (mm)

Abrasive Concentration : Diamond

Vitrified Bond Wheel For Pcd Tools

Minimum Order Quantity : 1 Piece

Product Type : Diamond Wheel

Abrasive : Intermediate Grinding Action

Shape : Round

Abrasive Concentration : Diamond

Send Inquiry

Send Inquiry